Silicone Fiberglass fabric is one kind of high performance and multi-purpose compound material which is made of silicone emulsion coated fiberglass with unique technology.

Feature:

1. Heat and cold resistance, good performance in heat preservation.

2. High strength, soft and flexible.

3. Chemical resistance, oil and water proof.

Heat resistance, weather resistance, resistant to ozone, oxygen, light and so on.

5. High insulation performance, dielectric constant 3-3.2, breakdown voltage 20~50KV/MM.

Applications:

1. Electric Insulation: Silicone rubber coated fiberglass cloth features high grade of electric insulation and bear a load of high voltage. It fits for making products like insulation cloth and sleeves etc.

2. Non-metallic compensator: used as pipeline flexible coupling, non-metallic compensator helps to avoid damage caused by heat expansion and cold contraction. This material specially fit for use in industries of petroleum, chemical engineering, cement, iron and steel and energy sources due to its special features of temperature resistance, anti-corrosion, anti-aging, and good elasticity and toughness.

3. Anti-Corrosion function: It is good to be used as inner and outer anti-corrosion layer featuring excellent corrosion, resistance, temperature resistance and high strength. It proves to be an ideal anti-corrosion material.

4. Others: Apart from above application, it can also be used as sealing material, temperature resistance and anti-corrosion conveyor belt and packaging material.

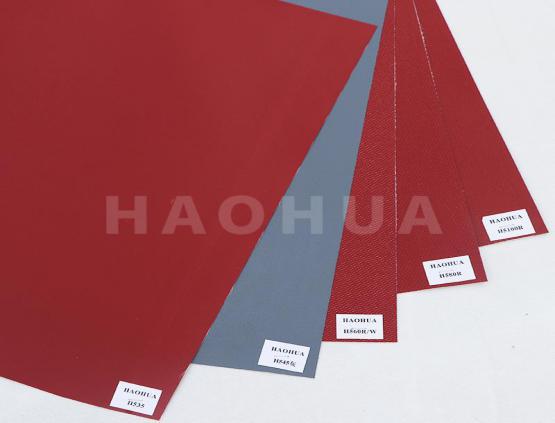

SPECIFICATIONS:

Silicone Coated Fiberglass Fabric | Item No. | Thickness(mm) | Fiberglass Weight(g/m2)±5% | Total Weight with Coating(g/m2)±5% | Remark | |

H518W | 0.18±0.01 | 205 | 230 | |||

H525W | 0.25±0.02 | 205 | 390 | |||

H525R | 0.25±0.02 | 205 | 390 | Customer’s Thickness and Color Available | ||

H535R | 0.29±0.02 | 255 | 520 | |||

H540R | 0.40±0.02 | 339 | 600 | |||

H545R | 0.45±0.02 | 383 | 630 | |||

H550R | 0.50±0.02 | 538 | 680 | |||

H560W+R | 0.60±0.02 | 578 | 700 | |||

H580R | 0.80±0.02 | 790 | 950 | |||

H5100R | 1.00±0.03 | 852 | 1200 | |||

Chinese

Chinese English

English