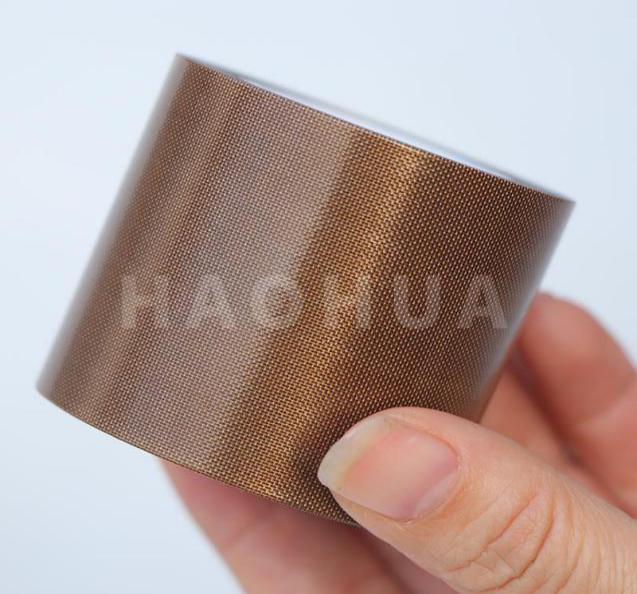

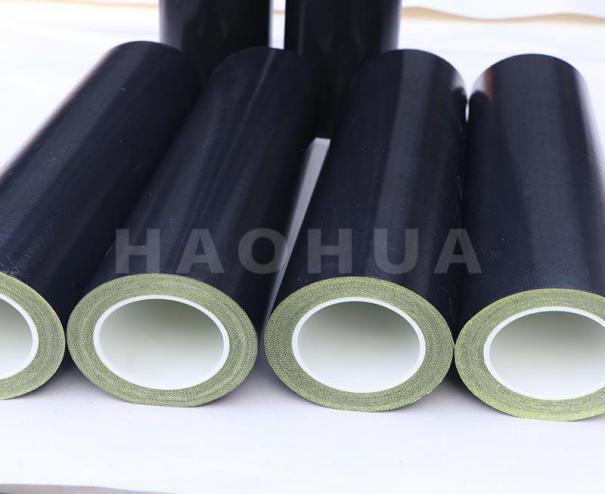

The PTFE tape is Silicone adhesive coated on PTFE fabric (or pure PTFE membrane) which has been sodium treated on single side.

Features:

1. Temperature resistance from -70°C to +300°C, with climate resistance and aging resistance.

2. Superior non-stick surface, easy to clean.

3. Excellent chemical resistance. Be Resistant to strong acid, strong alkali, aqua regia and various organic solvents.

4. Non-toxic, and can resist almost all pharmaceutical products

5. High insulating property, anti-UV, anti-static.

6. Fire Proof

7. Easy to apply, long working life.

Applications:

1. Coating on all kinds of high temperature rollers, heating plates, stripping pieces.

2. Heat sealing for foods, medicines and plastic package.

3. Can be used repeatedly and easy to be replaced as liners of chutes, hoppers, and aero moulds, also on the sizing machine rollers and demoulding industry.

4. Adapted for the surface treatment of non-adhesive, chemical resistance and temperature resistance.

5. Used in packing, thermoplastic, composite, sealing heat binding, electrical and electronic industries.

PTFE Fiberglass Adhesive Tape | Item No. | Color | Fiberglass Thickness (mm) ±0.02 | T Adhesion Thickness | Total Thickness | Adhesive Strength (To Steel) | Docking test (Times) | (High Temperature Peeling Test) |

H705 | Brown | 0.045 | 0.04 | 0.08 | ||||

H708W | White | 0.75 | 0.055 | 0.13 | ≥15 | ≥3 | Not Peeled in half hour 260℃ | |

H708 | Brown | 0.75 | 0.055 | 0.13 | ||||

H708B | AS Black | 0.08 | 0.05 | 0.13 | ||||

H711 | Brown | 0.11 | 0.05 | 0.16 | ||||

H711B | Black | 0.11 | 0.05 | 0.16 | ||||

H711W | White | 0.18 | 0.05 | 0.16 | ||||

H712 | Brown | 0.12 | 0.05 | 0.17 | ||||

H713 | Brown | 0.13 | 0.05 | 0.18 | ||||

H713B | Black | 0.13 | 0.05 | 0.18 | ||||

H715 | Brown | 0.15 | 0.05 | 0.20 | ||||

H718 | Brown | 0.18 | 0.05 | 0.23 | ||||

H725 | Brown | 0.24 | 0.06 | 0.30 | ||||

H735 | Brown | 0.33 | 0.07 | 0.40 | ||||

H713A | Acrylic | 0.08 | 0.05 | 0.13 | ||||

H718WS | White | 0.18 | 0.05 | 0.25 | One side PTFE, one side Silicone | |||

Chinese

Chinese English

English